Quality Assurance

Quality Policy

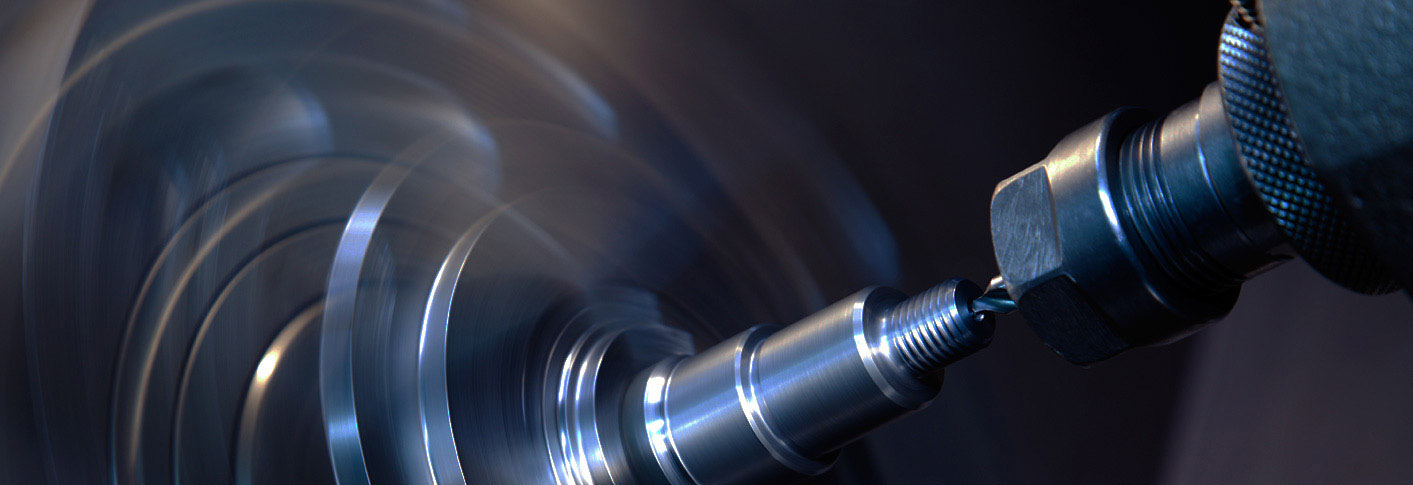

Racer tooling is committed to

Provide “Quality Excellent Design and manufacturing of molds, precision plastic components” Deliver on time and cost effective which satisfy the customer’s expectation through

- Team effort

- Technology upgradation

- Continually Improving our Performance and QMS

- Safety environment

- Close interaction with customer, supplier and other interested parties.

Quality Assurance

Racer Tooling Industries continuously reviewing, improving upon and documenting the quality practices, standards for our operation. We strive to provide products and services that consistently meet or exceed our customer requirements with the following certification,

- IATF16949:2016

- ISO9001:2015

Our Quality Assurance is proud to offer its accumulated experience through advance product with established a metrology lab with modern equipments run by qualified staff including:-

- High Performance VMS

- Spectrophotometer

- Gear checker

- Height Gauge

We implement variety of quality tools to resolve issues related to quality:-

- Failure Mode and Effects Analysis (FMEA)

- Process Control Plan – for individual product, secondary process and assembly

- Statistical Process Control (SPC)

- 7 QC Tools for problem analysis

- 8-D Corrective Action

- Process Capability Study (CPK)

- Problem Solving Sheet